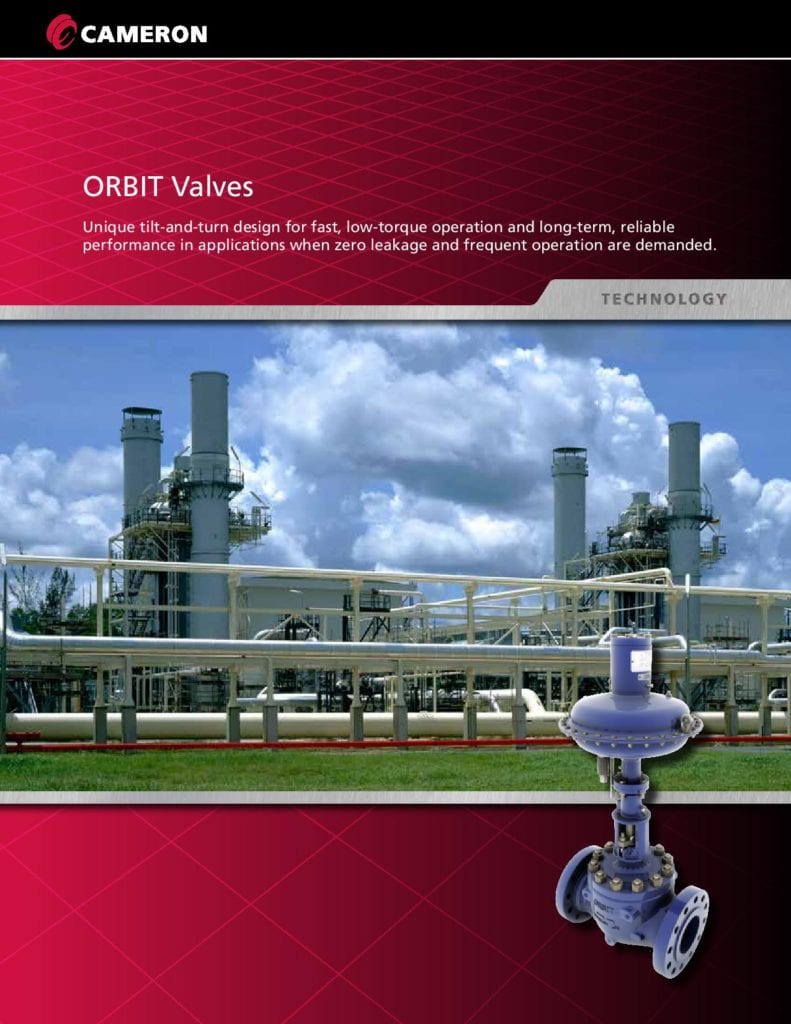

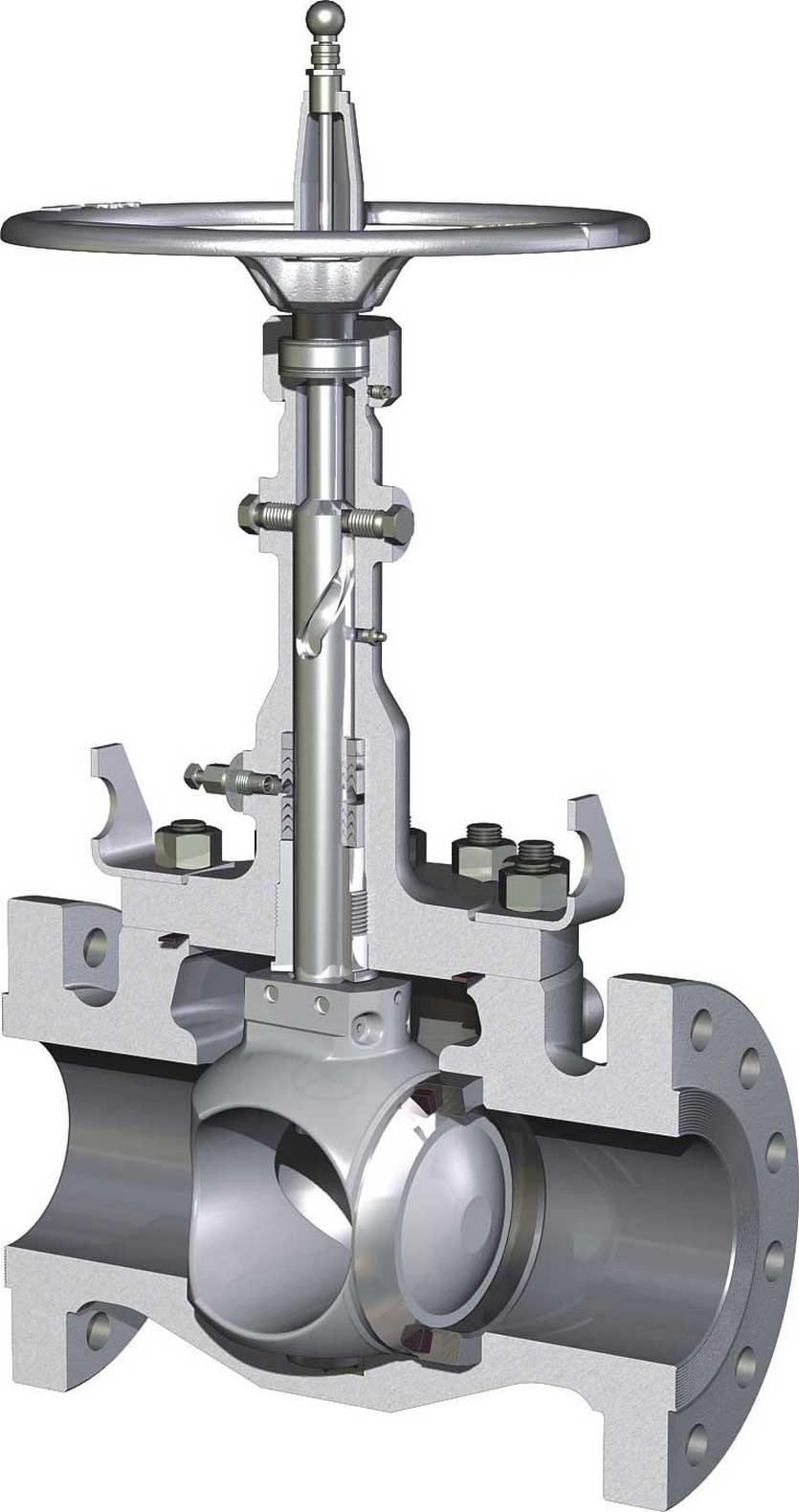

ORBIT Rising Stem

Ball Valve

ENERGY PRODUCTS CO.

IN STOCK:

-2″ through 8″

-150# – 600#

-TRIMS (T3 & T7)

-SEAT TYPES:

(H -20F – 500F)

(H8 -20F – 800F)

ALSO AVAILABLE:

-900#

-Modified Trims

-Parts

-Actuation

-Extended Testing

-Special Coatings

History of ORBIT VALVE

These were products born out of ideas Heggem conceived while working for the U.S. Bureau of Mines on trips to the early oil fields of Oklahoma, West Virginia and Texas. His inventions and concern for oil and natural gas conservation earned him the title, ‘Petroleum Engineer’ – the first known occurrence that title was ever given.

His groundbreaking ball valve seating principle, patented in 1935, was considered by many at the time to be the first major advancement for valves in half a century. Nearly 80 years later, the same engineering technology is still used to safeguard against seat rubbing – a leading factor for why ORBIT valves today are world-renown for high integrity and long service life.

Cameron acquired ORBIT in 1998. Today, ORBIT valves are used in over 88% of gas processing plants using molecular sieve systems in switching service, and 85% of LNG facilities worldwide. ORBIT valves are also in service in Exploration, Gathering, Production, Transportation and Process applications.

Because ORBIT maintains a uniquetilt-and-turn design to eliminate seat rubbing and withstand high temperatures under harsh conditions, these valves are some of the most sought after products for the most difficult applications in oil, gas and petrochemical industries.