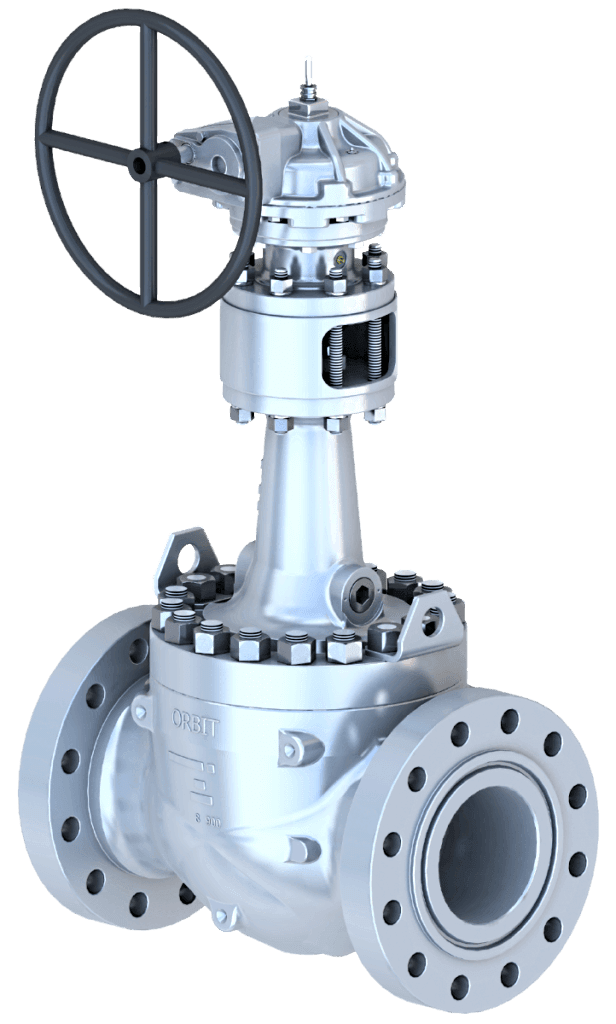

ORBIT VALVE

Rising Stem Ball

Stock available today in 2″ – 12″, ANSI 150# – 900#

Carrying T3, T5 &T7 Trims with H & H8 seats options

ORBIT rising stem ball valve’s unique tilt-and-turn design reduces seal rubbing and delivers reliable performance. It is the proven technology for arduous process conditions, including high-temperature, critical isolation to molecular sieve switching services. This legacy of innovation began in 1912, when Alfred Heggem founded The Oilwell Improvements Company of Tulsa. Heggem’s groundbreaking ball valve seating principle, patented in 1935, was considered by many at the time to be the first major advancement for valves in half a century. This patent is the forerunner to all ball valves today.

Nearly 80 years later, the same engineering technology still is used to safeguard against seat rubbing—a leading factor for why ORBIT valves are world-renowned for high integrity and long service life.

ORBIT Low-E certified low emissions valve

Not all valves are created equal. Only ORBIT Low-E valves incorporate new sealing elements that have earned certification to ISO 15848 Tightness Class AH and API Standard 622 for both high- and low-temperature applications. By integrating advanced graphite-based technology with the proven ORBIT valve tilt-and-turn operation, ORBIT Low-E valves set a new benchmark for fugitive emissions (FE) performance at temperature extremes while increasing valve life even under dynamic cycling conditions.